Amphibia Watch History

“… 10… 7… 5. Inevitably, the car wheel gradually moves. People stiffened with bated breath. What will it be?… 3… 1 meter and at last the thing that people expected with such curiosity finally happened: the wheel of Volga rolled over the… watch.”

This is how newspapers described the demonstration of “Amphibia” –

the first Soviet waterproof watch – capabilities in 1967. Today its creators tell us about the birth and features of this model.

Mikhail Novikov:

The task was this: to develop a watch that is not inferior to foreign analogs and can function reliably at a depth of up to 200 meters in the conditions of considerable pressure differences and temperature.

At that time, I was the chief of New Design Bureau and generally worked on “Amphibia”. The name was thought up by one of our employees. We held a peculiar competition for the new watch’s name and chose “Amphibia” for symbolizing being equally comfortable both in water and on land.

At that time there was a set of waterproof watches of various designs produced in Switzerland. It would seem that we didn’t have to reinvent the wheel. But we couldn’t repeat the designs as our equipment didn’t allow to provide the required accuracy. Besides, almost all designs were protected by patents and it was impossible to copy them. The question of the patent acquisition didn’t even arise, as far as I remember, there was no attempt to purchase a patent or a license in the USSR. We patented our work, protected it, and didn’t buy “their” patent.

I studied patents for the waterproof watch, the so-called 43rd class, very carefully. But the stories about Italian and other watches for submariners and I learned and began collecting later when work on “Amphibia” was completed.

Our task was not in finding a technical solution but in finding the same effective solution, as good as foreign examples were (if possible, find better), but not patent. And we developed our own design which could be manufactured and which didn’t repeat someone else’s. Of course, at the same time, many options of sealing were considered, we rated them by the efficiency of sealing and the cost.

And the car rolling over the watch was just a demonstration of its durability and had nothing in common with real testing. The pressure at the maximum depth is several times more than the pressure of the tire upon the road, but the mechanical pressure and pressure in liquid work differently, and it is impossible to compare them.

At the first glance “Amphibia” doesn’t differ from a usual watch. But actually almost all elements of the case here are special and it was necessary to tinker with each of them.

Let’s take glass: it is almost not noticeable, but it has a special cross-section. Glass is under pressure of 20 kg/cm2, it is several times more than the pressure of car tire upon the road. With such pressure glass caves in on 0,5 mm. When caving in and flattening a little, it has to additionally pressurize the case and at the same time not touch the second hand. It is difficult to calculate bending even for flat glass, and far more difficult for “Amphibia’s” glass.

Vera Belova

“Amphibia’s” glass is thicker than usual: if “Komandirskie” has 2 mm, then for it is 3 mm. But the point is not only in thickness and configuration: it is also made by special technology. Unlike usual glass, it isn’t just cast from plastic but it is also ground away. To provide tightness with a big pressure very high precision on diameter is necessary and even the slightest scratches on a contour are inadmissible. To achieve all this, glass is ground the.

Mikhail Novikov:

It would seem that what could be simpler than rubber laying? Sometimes they say: you get one from a water tap. But requirements to rubber laying in “Amphibia” are much tougher. In a usual watch its thickness is 0,5 mm and in “Amphibia” it is 0,75 mm. Under the pressure of 20 atm laying is compressed in size by 20-30%. If you squeeze the rubber band from the tap like that it won’t be straightened back, residual deformation is too big. And our laying has to restore its initial form completely. Add temperature drops here, and you will understand all complexity of a problem. To provide the set parameters, it was necessary to develop not only details but also materials. For achievement of necessary laying characteristics at one time, we even tried to process them by an ionic method – the technology that is used in space equipment.

Vera Belova:

We were choosing rubber for a very long time. To avoid leaks the rubber had to be smooth, without pores. For a regular watch we used laying from usual rubber from the Kazan plant of rubber products. They are good for small pressure but cannot maintain the big one. That’s why we made laying for “Amphibia” at the plant ourselves, producing it from crude rubber and then cutting.

Mikhail Novikov:

There were problems with other materials too. The case of “Amphibia” was for the first time made not out of brass but out of stainless steel. The steel case is better: it is stronger, more durable, and, besides, it is anti-allergenic.

Traditionally the case is manufactured like that: we cut work pieces of the case from brass tape on a special press, it is later ground, chiseled, etc. But steel is much more tough than brass. And we couldn’t cut work pieces of the necessary form for a long time: “ears” to which the watch band fastens broke off constantly. Therefore the first cases were with “fragments” instead of actual ears. Then we tried to cut the case in 12 stages. But it also did not go very smoothly.

By the way about steel, from which the cases are made. When the “Amphibia” was developed there was no such brand of steel produced in the country. And we had to add a new position to the GOST (the state standard).

Vera Belova:

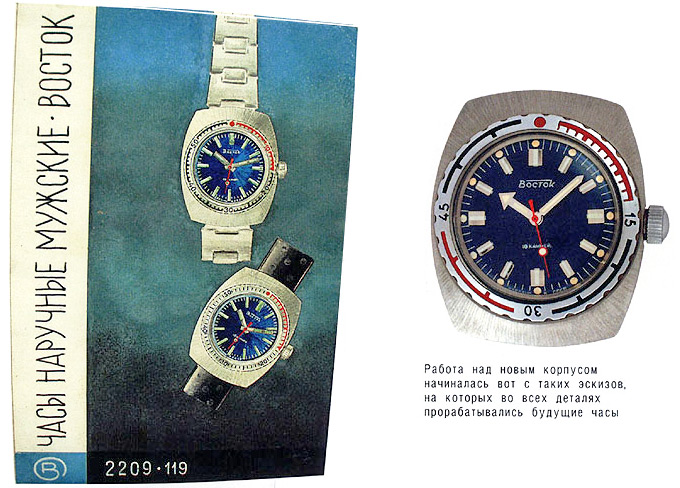

The change in the case has concerned not only material. The screwing-up head and the timing disk (bezel) have been used on “Amphibia” for the first time. If before immersion you set “O” on the disk against a minute hand, then it will be possible to determine the time spent under water. Only in the 90s these elements have appeared on the “Komandirskie” watch. The back cover was special too: instead of 0,5 mm, it was 1 mm thick. Even the screw which holds a cover has been strengthened.

Mikhail Novikov:

After creation of “Amphibia” according to our proposal, the international standard for scuba diving watch was changed. A condition was added that if one applies pressure perpendicularly to the head or buttons of a watch under water no moisture should get in the watch. Of course, “Amphibia” met this requirement.

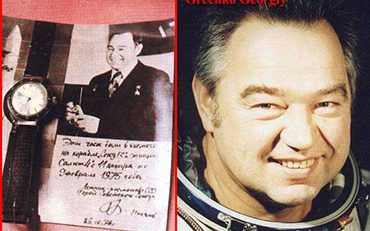

Also, military modification NVCh-30 of “Amphibian” was issued. When seamen came to NIICHASPROM with the order for diver watch, they were told that they already produce a similar model in Chistopol. To provide the hermeticity required for 30 atm pressure we had to modify serial “Amphibia”. In NVCh-30 there was a different glass configuration and thicker cover.

Vera Belova:

These watches were tested according to a very tough program. Even the watch band was checked for durability. By the way, the band of NVCh-30 had the unique fastening that was a little strange in appearance but very strong.

Mikhail Novikov:

The main part of tests was carried out in NIICHASPROM, and the component acceptance test was passed during maneuvers of the fleet in the North Sea. By the way, there was a rehearsal of something similar to the rescue of Kursk crew. The submarine laid down on the bottom at a depth of 120-130 meters, imitating accident. There were two saving ships, the enormous pontoon crane “Carpaty”, diving bells, decompression cameras, and a crew of divers. The scheme of operation is this: the bell goes down from the ship, it is set on the special attached platform by the boat, it is forced to it by the pressure. People go from the boat into the bell and they are lifted up to the decompression chamber. During that training, we lifted one group of six people. Divers who worked at depth had our watches. Both tests and maneuvers went well.

During this training, the watches were tested at maximum depths of more than 100 meters though really they intended for other purposes. Deep-water divers have a continuous radio communication with the ship and in their heavy equipment, it is simply inconvenient to look at the watch at such depth. But for scuba divers and fighting swimmers our NVCh-30 were irreplaceable.

Leave a Reply